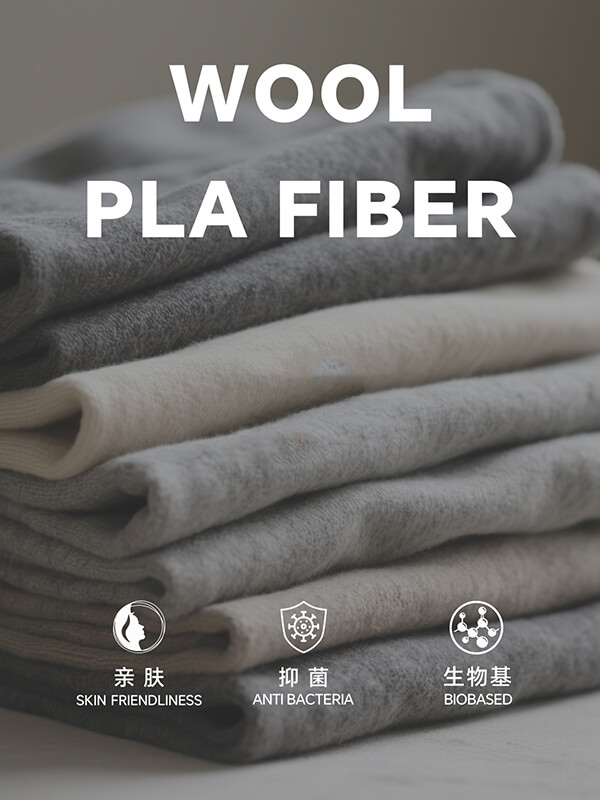

PLA fiber and Wool Blends Deliver Comfort, Performance, and Eco-Friendly Appeal

Wool and cashmere are cherished in the apparel industry for their natural softness, thermal insulation, breathability, and lightweight feel—qualities that make them ideal for skin-friendly, warm garments. However, these natural fibers also come with certain limitations: untreated wool tends to lose its shape, pill easily, and may yellow if not stored or handled correctly.

As environmental awareness and demand for sustainable materials grow, polylactic acid (PLA) fiber, a bio-based synthetic derived from renewable resources, has emerged as a promising alternative. When blended with wool or cashmere, PLA offers a unique set of performance benefits, transforming traditional woolen products into versatile, eco-conscious textiles.

Why Blend PLA Fiber with Wool?

1. Antibacterial and Hypoallergenic Benefits for Everyday Wear

PLA fibers are naturally breathable and soft, with built-in antibacterial and anti-mite properties. When mixed with wool or cashmere, the resulting fabric maintains wool's warmth and plush feel while gaining PLA's lightweight structure and fast-drying characteristics. The blend enhances comfort and hygiene—especially valuable in close-to-skin clothing like sweaters, knitwear, and thermal underlayers.

2. Better Structure and Shape Retention

Combining PLA with wool, cotton, linen, or silk improves fabric stiffness and shape retention. This is particularly useful in structured garments such as blazers, tailored coats, and other outerwear, where crispness and durability are essential.

3. A Cost-Effective Solution with Lower Wool Dependence

By incorporating PLA into blends, manufacturers can maintain high-quality textile performance while reducing reliance on expensive wool, thus achieving cost savings without sacrificing product value.

Diverse Applications Across Apparel and Home Textiles

Apparel Use Cases

In garments like knit tops, sweaters, base layers, and performance underwear, PLA-wool blends deliver a balanced combination of thermal insulation and skin-soothing softness. The functional attributes of PLA—such as anti-allergy and antibacterial performance—meet the evolving demands of health-conscious consumers.

For instance, esunfiber, in partnership with leading textile developers, has created a successful 65% wool and 35% PLA fiber sweater. This innovation effectively resolved key technical challenges such as dyeing, finishing, and yarn uniformity. The final product is lightweight, comfortable, warm, and functionally antimicrobial—offering an excellent wearing experience.

In more structured garments like suits and overcoats, the blend enhances durability and resistance to pilling while improving fabric drape and reducing overall garment weight.

Home Textile Applications

PLA and wool blended fibers are also making strides in home textiles. They serve as ideal materials for:

Blankets and quilt fillings: Lightweight, warm, and more resistant to shrinkage and deformation compared to pure wool.

Carpet and cushion covers: Durable yet soft, these blends suit premium, environmentally friendly home decor products.

Nonwoven fabrics: Through needle punching or hydroentangling, PLA-wool blends can also be used in technical textiles or functional household goods.

Moving Toward a Greener Future in Textiles

As sustainability becomes a central concern across industries, the textile sector is increasingly seeking solutions that combine environmental responsibility with product functionality. The fusion of PLA fiber and wool is a forward-thinking approach that aligns with this trend—supporting low-carbon, functional, and fashion-forward development in wool-based products.

esunfiber, a pioneer in PLA nonwoven fiber solutions, is dedicated to leading the market in differentiated and high-performance bio-based materials. With continuous breakthroughs in core PLA technologies, esunfiber welcomes collaboration opportunities and encourages joint efforts to drive sustainable progress in the textile industry.